-

By magnet

-

January 23, 2026

- 0 Comment

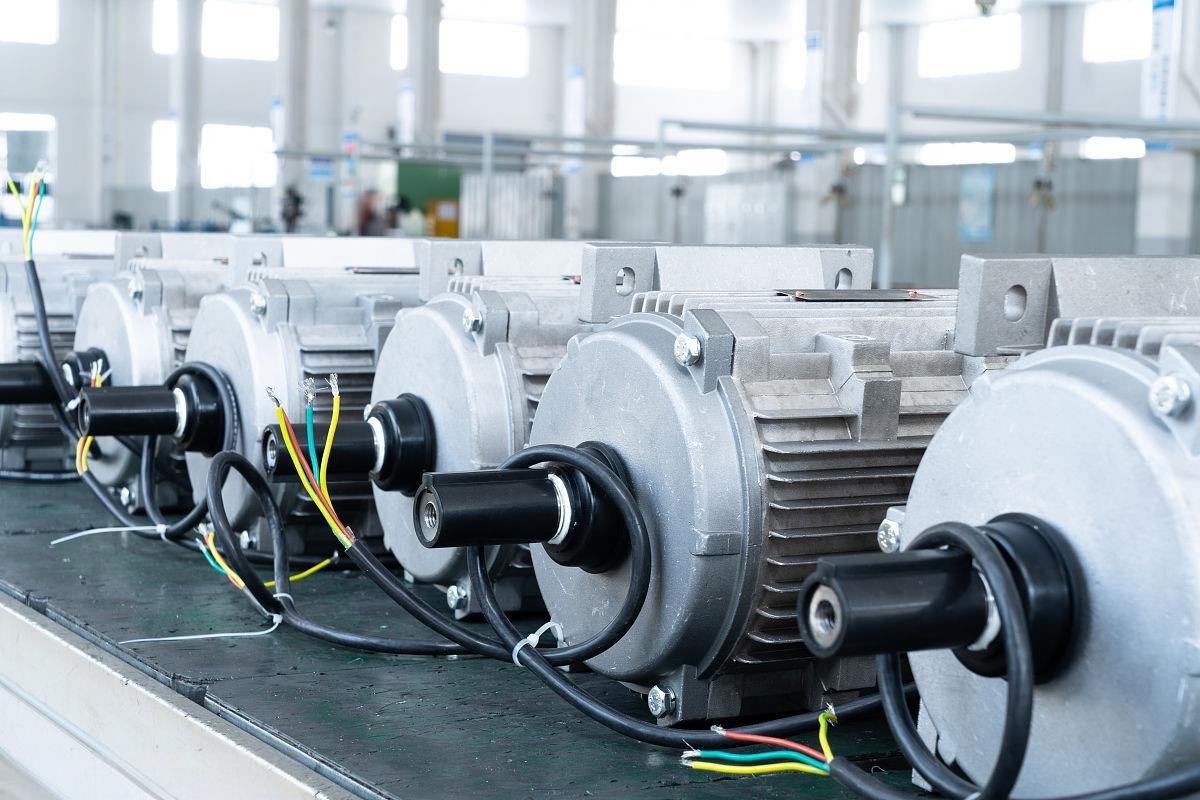

Customized Permanent Magnet Motor

As a business owner or production operation & maintenance manager, are you always troubled by these personalized problems: does a high-temperature and high-humidity production environment cause frequent motor overheating failures? Can’t you find a motor that matches equipment with special speed requirements and installation dimensions? Does the energy-saving effect of a general-purpose motor drop significantly under variable-load conditions, wasting electricity costs?

In fact, the core solution to these “non-standard” problems lies in customized permanent magnet motors. As a manufacturer that has been deeply involved in the customized motor field for many years, we rely on an experienced R&D team, full-chain technical reserves, and a strict quality control system to deeply understand the core needs of enterprises across different industries and operating conditions. Today, from the perspective of actual business operations, we will talk about the core value of customized permanent magnet motors and how we use professional capabilities to precisely solve your specific production pain points.

I. Customized Energy-Saving Solutions: More Precise Electricity Cost Savings

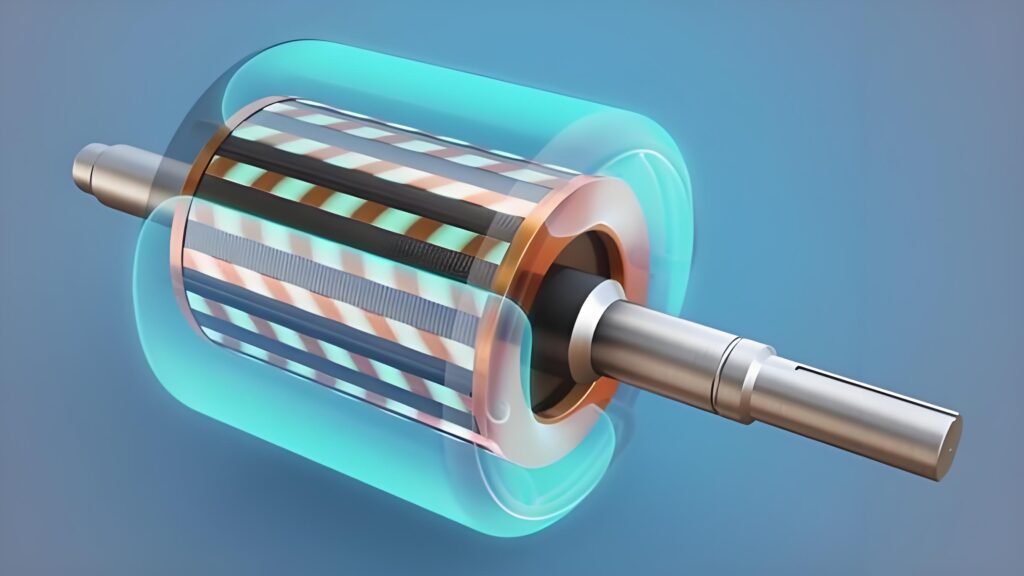

For industrial enterprises, motor energy consumption accounts for more than 60% of total production energy consumption, and electricity expenses directly affect profit margins. The most prominent advantage of permanent magnet motors is “saving electricity costs”. Compared with traditional induction motors, they use rare-earth permanent magnets to establish the magnetic field and do not need to additionally consume electrical energy to generate excitation, completely eliminating rotor losses. Overall efficiency can reach 92%–96%, far exceeding the 85%–90% of ordinary motors.

More importantly, customized permanent magnet motors can “prescribe the right remedy” according to an enterprise’s specific operating conditions to maximize energy-saving results. We have established a standardized pre-sales technical service process. Through three core steps—on-site operating condition survey, load characteristic analysis, and precise parameter matching—combined with core technologies such as magnetic circuit optimization design and customized winding processes, the motor is kept operating in a high-efficiency range. For typical operating conditions in industries such as power, rubber, and chemical, we have formed a mature customized energy-saving solution system: for example, for fan-type equipment with low speed and high torque, a direct-drive structure design is adopted to remove redundant transmission components, greatly reducing energy consumption; for high-temperature operating conditions, customized water-cooling/air-cooling heat dissipation systems and high-temperature-resistant magnet materials are used to achieve precise energy savings while ensuring stable operation, helping enterprises significantly reduce electricity costs and shorten the payback period of equipment investment.

II. Customized Protection and Structure: Reducing Downtime Maintenance Costs

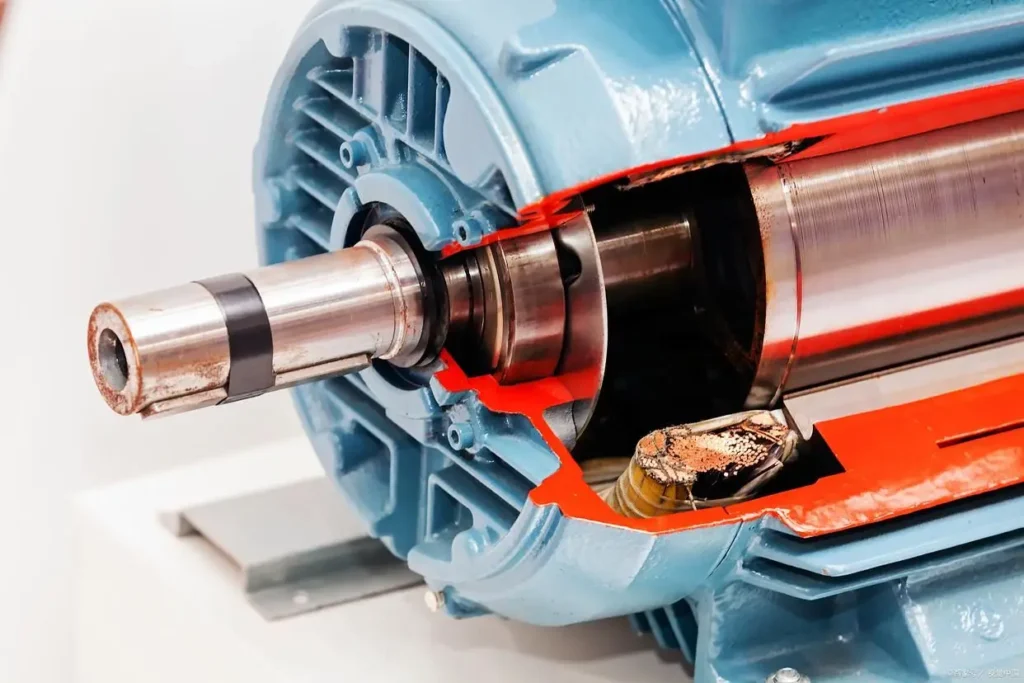

For production-oriented enterprises, “downtime means losing money”. Components such as gearboxes and brushes in traditional motors are high-incidence failure points. They not only require regular oil changes and maintenance, but once problems occur, they can also cause the production line to stop. Permanent magnet motors have a particularly simple structure. Especially with a direct-drive design, intermediate transmission links such as gearboxes and clutches can be eliminated directly, greatly reducing failure points.

We have long been engaged in motor customization for harsh operating conditions and have complete protection-solution design capabilities. For complex environments such as high temperature and humidity, dust corrosion, and dye splashing, technical measures such as customized anti-corrosion coatings, optimized sealing structures, and closed-loop circulating cooling systems can be used to raise the motor protection level to IP55 or above, fundamentally solving the pain points of general-purpose motors being prone to corrosion and overheating. At the same time, relying on a direct-drive structure to reduce failure points, together with customized lubrication solutions and material selection, motor operating stability and service life are greatly improved, significantly reducing downtime losses and O&M labor costs, and ensuring production continuity.

What is even more worry-free is that our customized permanent magnet motors can be equipped with an intelligent monitoring system as needed. By collecting key parameters such as temperature, current, and speed in real time and combining them with big-data analysis, early fault warnings can be realized, allowing enterprises to completely say goodbye to “passive maintenance”.

III. Full-Scenario Customized Adaptation: Supporting Production Line Upgrades and Iteration

One of the core advantages of customized permanent magnet motors is that they can break through the adaptation limitations of general-purpose motors and be precisely adjusted according to enterprise equipment needs. Whether it is power range, speed requirements, installation method, or protection requirements, we can achieve perfect adaptation through modular design and parametric customization. This high flexibility makes the motor smaller and more compact, saving plant space, and is especially suitable for upgrading and renovating old factories.

Based on a modular design concept and fully adjustable parameters, we can precisely match the core needs of different industries: for textile-industry equipment with low-voltage grid characteristics and frequent start-stop needs, we customize low-voltage permanent magnet motor solutions, optimize starting current control, reduce grid impact, and improve operating stability; for the machine-tool industry’s high-precision machining requirements, by adding high-resolution feedback components and dedicated control algorithms, ±0.1% speed control accuracy is achieved, helping improve machining precision and reduce scrap rates; for the new energy industry’s fast response requirements, we optimize the motor electromagnetic design to achieve millisecond-level response speed and improve equipment operating efficiency. From traditional industry to high-end manufacturing, we can provide customized solutions that fit the operating conditions.

From printing and dyeing plants with high temperature and high humidity, cement plants with heavy dust, to high-precision machine-tool workshops and photovoltaic power stations in harsh outdoor environments, our customized permanent magnet motors can be precisely adapted through dedicated designs, becoming an “exclusive helper” for enterprise production line upgrades.

Choosing the Right Customized Permanent Magnet Motor Means Choosing a Long-Term Partner for “Precise Cost Reduction”

For enterprises, choosing a customized permanent magnet motor is not a simple “equipment replacement”, but choosing a set of precise cost-reduction and efficiency-improvement solutions that fit their own operating conditions. It not only significantly reduces short-term electricity and maintenance costs, but also improves production efficiency and expands capacity space through long-term stable operation.

If your enterprise is also facing problems such as difficulty adapting to non-standard operating conditions, poor energy-saving performance of general-purpose motors, and frequent equipment failures, feel free to contact us. Relying on an experienced R&D team, multiple core technology patents, and a full-process service system, we provide an integrated solution of “pre-sales operating condition diagnosis – in-sales customized production – after-sales technical support”: the technical team analyzes operating conditions, combines load characteristics and environmental requirements, and outputs a customized design solution; the production stage adopts strict quality control standards to ensure stable product performance; and follow-up provides technical support and regular operation and maintenance guidance. Choosing us means choosing a long-term partner that relies on professional technology to achieve precise cost reduction.