What we do

Hangzhou BOMAG ELECTRIC MOTOR Co,Ltd.

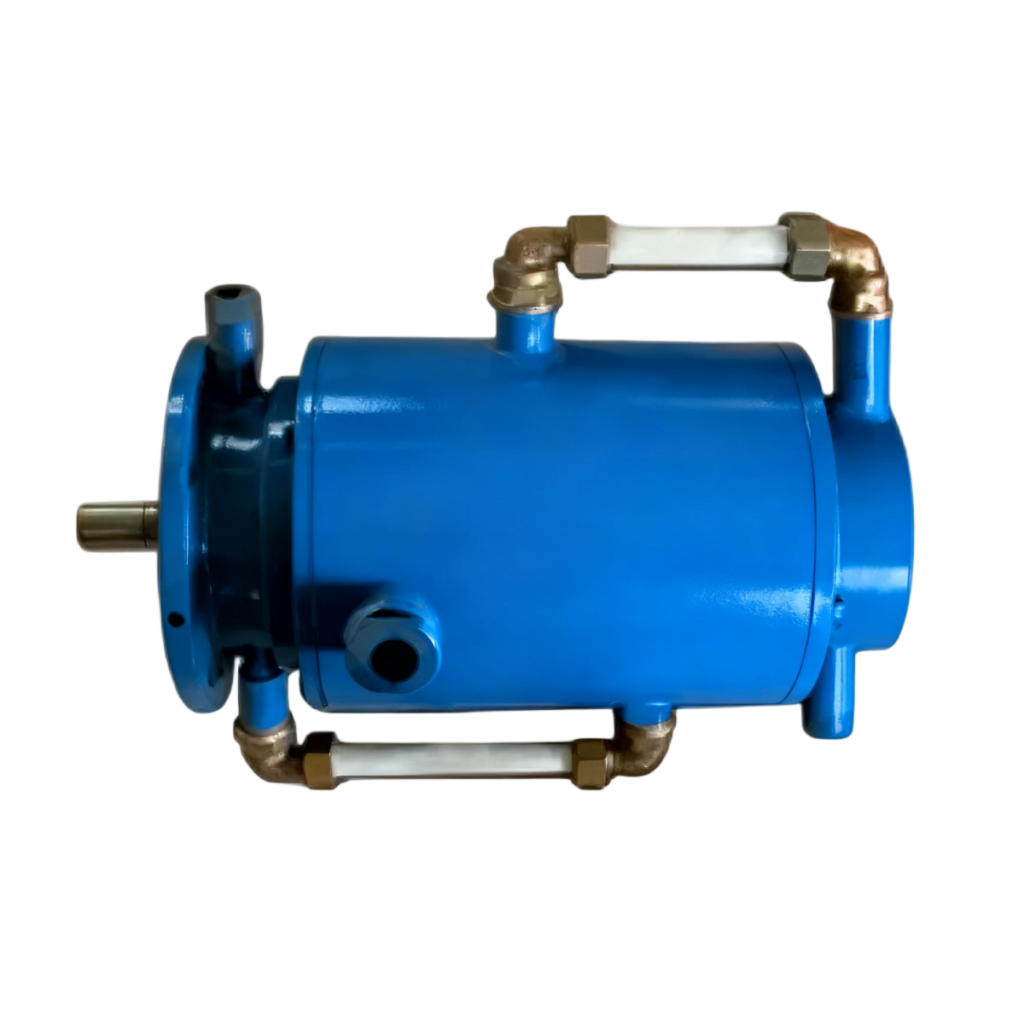

BOMAG ELECTRIC MOTOR is a professional motor manufacturer with a core team of experienced professionals. Its products are widely used in rail transportation, industrial automation, medical devices, new energy vehicles, and other fields. From design and sample testing to mass production and quality inspection, the company consistently adheres to high-quality standards, providing customers with reliable motor products and one-stop solutions.

Experience

0

+

Workers

0

+

Customers

0

+

countries

0

+